Description

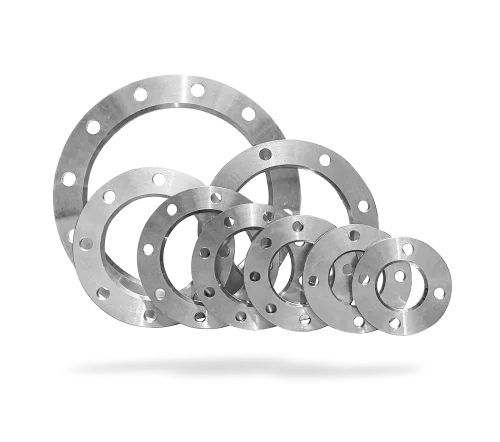

A flat flange represents a robust and versatile solution for connections in piping systems, being widely used across various industries. Alongside blind flanges and loose flanges, they form a comprehensive range of components that ensure the optimal functioning and safety of industrial systems. Regardless of the type of flange chosen, it is essential to consider the operating conditions, the nature of the transported fluid, and the requirements for sealing and durability. By understanding their characteristics and applications, engineers and technicians can make informed choices that contribute to the long-term efficiency and reliability of systems.

Flanges are fundamental components in the industrial and engineering world, playing a crucial role in ensuring secure and sealed connections between pipes, equipment, or devices. These linking elements allow the efficient transfer of fluids, gases, or other substances, being indispensable in piping systems across various industries such as oil and gas, energy, chemicals, or food. Among the most commonly used types of flanges are flat flanges, blind flanges, and loose flanges, each with specific characteristics and applications that make them suitable for different purposes. In this context, the flat flange stands out for its simplicity and versatility, being one of the most widespread solutions for secure and durable connections.

The flat flange, also known as a “flat flange” in English, is a type of flange characterized by a uniform and flat contact surface. This feature makes it ideal for applications where a simple and efficient connection between two pipes or equipment is required. Flat flanges are often used in piping systems with moderate pressures, where sealing and strength are essential. They can be made from various materials, such as carbon steel, stainless steel, or special alloys, depending on the operating environment and requirements for corrosion resistance, high temperatures, or intense pressures. For example, in the oil industry, stainless steel flat flanges are preferred due to their corrosion resistance and durability in aggressive environments.

In addition to flat flanges, blind flanges and loose flanges (slip-on flanges) also hold an important place in the range of connecting components. The blind flange is a specialized type of flange that does not have a central opening, being used to close or isolate the end of a pipe or vessel. This feature makes it particularly useful during maintenance, repairs, or testing, allowing the isolation of certain sections of the system without affecting the rest of the piping network. Blind flanges are often used in the chemical or energy industries, where safety and sealing are priorities. On the other hand, loose flanges are designed to “slip” over the end of a pipe, offering increased flexibility in terms of assembly and alignment. These are often chosen for projects where quick installation or precise adjustment of components is required.

Flat flanges, however, remain one of the most popular options due to their simplicity and efficiency. They are easy to install and can be used in a wide variety of applications, from water distribution systems to gas or oil transport pipelines. Additionally, flat flanges are compatible with various types of gaskets, allowing them to provide optimal sealing under varying conditions. Moreover, they can be used both in combination with other types of flanges and as standalone elements, offering increased flexibility in the design and construction of piping systems.

An interesting aspect of flat flanges is that they can be customized according to the specific needs of each project. For example, in applications involving extremely high temperatures or intense pressures, flat flanges can be made from special materials, such as nickel or titanium alloys, which offer enhanced resistance to heat and corrosion. This makes them suitable for use in thermal power plants, refineries, or offshore oil platforms, where operating conditions are particularly demanding.

| Ordea code | PN / DN |

| 3712092 | Flat flange PN/16 DN350-377 STAS 8014 |

| 3712969 | Flat flange PN10 DN200-219 |

| 3712091 | Flat flange PN10 DN300 STAS 8014 |

| 3714466 | Flat flange PN10 DN450 |

| 3710934 | Flat flange PN10/16 DN100 STAS 8014 |

| 3711180 | Flat flange PN10/16 DN125 STAS 8014 |

| 3710328 | Flat flange PN10/16 DN150-168 STAS 8014 |

| 3711265 | Flat flange PN10/16 DN50 STAS 8014 |

| 3711266 | Flat flange PN10/16 DN65 STAS 8014 |

| 3711267 | Flat flange PN10/16 DN80-89 STAS 8014 |

| 3710327 | Flat flange PN16 DN200 STAS 8014 |

| 3711758 | Flat flange PN16 DN250 STAS 8014 |

| 3715199 | Flat flange PN16 DN80 filet 3″ |