Description

An Above Ground Hydrant is a fundamental element of fire protection infrastructure, playing a crucial role in ensuring public safety and protecting property. They are essential devices for supplying the water needed by emergency crews during fires. Understanding their purpose and use is therefore vital for effective emergency management.

Providing a Water Supply for Fire Fighting

The main purpose of fire hydrants is to provide an immediate and reliable source of water for firefighters and other fire crews in the event of a fire. Water is essential for extinguishing the fire and limiting its spread, thereby reducing the risk of property damage and loss of life. Hydrants are connected to the drinking water network or water reservoirs, thus ensuring the continuous availability of water in large quantities.

Protection of Life and Property

By providing a quick source of water, fire hydrants make a significant contribution to protecting life and property. Fires can spread quickly and cause devastating damage; therefore, quick access to water is crucial for damage limitation. Hydrants allow emergency crews to act promptly and efficiently, reducing the time it takes to extinguish a fire. Fire hydrants are an essential component of public safety infrastructure. They are strategically installed in residential, commercial and industrial areas, as well as public spaces, to ensure quick and easy access for emergency crews. This contributes to a safer environment for all citizens.

Use of Fire Hydrants

In the event of a fire, fire hydrants are used by fire crews to connect fire hoses and deliver water directly to the fire scene. The procedure for use involves opening the hydrant valve to allow water to flow and direct it to the fire.

It is important that firefighters are well trained in the use of hydrants to ensure quick and efficient operation. To ensure proper operation and reliability, hydrants must be tested and maintained regularly. Regular tests include checking water pressure and flow, inspecting mechanical components and lubricating moving parts.

Regular maintenance

Prevents blockages and damage, thus ensuring the availability of hydrants in case of need. The effective use of hydrants requires adequate training for emergency crews. Firefighters must be familiar with the location of hydrants, operating mechanisms and hose connection procedures.

In some cases, hydrants may also be used for non-emergency purposes, such as filling the water tanks of street maintenance vehicles or for urban cleaning activities. However, their use for such purposes must be carefully managed so as not to compromise the availability of water in case of fire.

This is an Above Ground Hydrant, for underground hydrants check the version Underground Hydrant DN80 PN10 PN16.

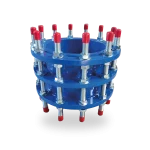

The hydrant body is made of ductile cast iron GLJ250, ensuring durability and high resistance to corrosion and wear. Valves and internal mechanisms are made of brass or stainless steel to prevent blockage and ensure reliable operation in all conditions.

Dimensions and weight:

This hydrant is available as standard in three heights: 1924mm, 2174mm and 2474mm and can be installed at 1250mm, 1500mm and respectv 1800mm. For heights other than these standards, speak to a Homplex specialist about the solutions available. The nominal diameter of the main pipe is 100mm and the total weight of the hydrant is approximately 50-80kg depending on size.

Purpose and Use

- The main purpose of the fire hydrant is to provide a quick and reliable source of water for fighting fires. This helps prevent the spread of fire and minimizes fire damage.

- Installation and Distribution:

Hydrants are installed in public areas, such as streets, squares and parking lots. pPeople also install hydrants near commercial, industrial and residential buildings.

In urban areas, hydrants are strategically distributed at intervals of 80-100 meters. This ensures quick and easy access for emergency crews. - Testing and Maintenance:

It is essential that hydrants are regularly tested and maintained to ensure their proper operation. This includes visual inspections, pressure and flow testing, and lubrication of mechanical components.

Hydrants should be clearly marked and identified with visible markers indicating their exact location. - Education and Training:

The proper use of fire hydrants requires specialized training for first responders and safety personnel. It is important that they are familiar with the operating mechanisms and hose connection procedures.

Benefits

- Safety and Protection: fire hydrants provide crucial defense against fire, protecting lives and property.

- Reliability: Durable materials and robust design ensure reliable, long-lasting operation.

- Compatibility: Standardized fittings allow the use of available fire equipment, facilitating rapid intervention.

Availability

In general, for standard versions, hydrants can be delivered immediately from stock. For special versions, the procurement and delivery time is very short.

Operations:

- Hydrants are opened and closed with a special key, according to STAS 706 – 80.

- Turn the key clockwise to the right to close the hydrant.

- The number of turns required varies: 11-12 turns for DN 80 and 9-10 turns for DN 100.

- The rotation of the actuating spindle is smooth and the movement of the fan should be smooth. Avoid hitting the operating cover.

Water evacuation:

- Above-ground hydrants have a vented drain hole.

- It allows water to drain from the column when the hydrant is closed.

- Make sure that it can be emptied during installation.

Assembly:

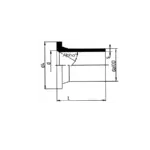

- The above-ground hydrants are vertically mounted on a reinforcement with flanges identical in diameter and dimensions PN 10 (16), according to PN-EN 1092-2:1999.

- Installation is carried out with the vent closed.

- Foot and flange elbows are recommended. The foot elbow is fixed to a rigid support (concrete).

- Avoid embedding the safety screws in the concrete during or after installation.

Regular checks:

- Perform periodic closing-opening maneuvers to check functionality, tightness and water discharge.

Remedies:

- In case of leaks, replace the vent.

- Replacement can be accomplished without dismantling by dismantling the upper part of the hydrant.

- First disassemble the push rod assembly.

- Reassemble the assembly in reverse, ensuring proper seating of the vent for draining and operation.

Recommendations:

- Ensure proper training and equipment.

- Follow local safety rules and regulations.