Description

The blind flange is a fundamental component in modern industry, and alongside flat flanges and loose flanges, it represents just a small part of the vast range of available options. Each type of flange brings unique advantages and is essential in specific applications, contributing to the efficiency and safety of piping systems and beyond. By understanding their characteristics and uses, engineers and technicians can make informed choices that ensure long-term performance and durability.

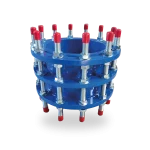

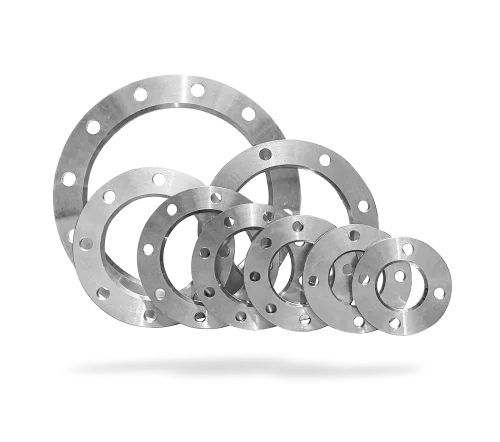

Flanges are essential components in the world of engineering and industrialization, serving as indispensable connecting elements in piping systems and more. They provide a secure and sealed connection between different sections of pipes, equipment, or devices, enabling the efficient transfer of fluids, gases, or other substances. Among the most commonly used types of flanges are flat flanges, blind flanges, and loose flanges, each with specific characteristics and applications that make them suitable for various purposes.

Flat flanges are among the most widespread and versatile, being used particularly in applications where a simple and efficient connection is required. They are designed to provide a uniform contact surface, allowing for easy installation between two pipes or pieces of equipment. Due to their simplicity, flat flanges are often chosen for general construction projects or in piping systems with moderate pressures. They can be found in various materials, such as carbon steel, stainless steel, or special alloys, depending on the environment in which they are used and the requirements for corrosion resistance or high temperatures.

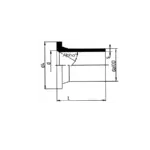

The blind flange, on the other hand, is a specialized type of flange that plays a crucial role in isolating or sealing a piping system. Unlike flat flanges, blind flanges do not have a central opening, which allows them to function as a “cap” or “cover” for closing off a pipe. They are often used to isolate sections of a pipeline during maintenance, repairs, or testing, ensuring there are no leaks or pressure losses. Blind flanges are particularly useful in the oil, chemical, or energy industries, where safety and sealing are of utmost importance. Additionally, they can be made from materials resistant to extreme pressures and temperatures, making them ideal for demanding working environments.

Loose flanges, also known as slip-on flanges, offer increased flexibility in terms of installation and alignment of piping systems. They are designed to “slip” over the end of a pipe, allowing for easy adjustment before welding or fastening. This feature makes them particularly useful in situations where quick installation or precise alignment of components is essential. Loose flanges are often used in combination with other types of flanges or in complex piping systems, where flexibility and ease of installation are priorities.

Regardless of the type of flange chosen, each has a distinct and vital role in ensuring the optimal functioning of industrial systems. Flat flanges, blind flanges, and loose flanges are designed to withstand varying conditions, from high pressures to extreme temperatures, and are made from materials that meet the specific requirements of each working environment. The choice of the right type of flange depends on a number of factors, including the nature of the transported fluid, operating conditions, and safety and sealing requirements.

| Order code | PN / DN |

| 3713461 | Blind Flange DN40 10/16 |

| 3710767 | Blind Flange PN10 DN200 |

| 3712752 | Blind Flange PN10/16 DN125 |

| 3710854 | Blind Flange PN10/16 DN150 |

| 3710855 | Blind Flange PN10/16 DN80 |

| 3710768 | Blind Flange ZN PN10/16 DN100 |