Methane sensors are more than just devices-they’re guardians of your safety. In industry they help prevent, detect and remediate gas leaks, protect communities from explosions, and slow climate change triggered by the greenhouse effect.

Methane is a silent but potent threat. As the main component of natural gas, it powers our homes and industries, but when it leaks out, it adversely affects the environment. Over a century, methane retains 28 times more heat than carbon dioxide. It is also explosive, posing a risk in mining, pipelines and landfills. Detecting methane leaks is not just about saving the planet; it’s also about saving lives. That’s where methane gas sensors come in: the unsung heroes working behind the scenes to spot leaks before they become disasters. Let’s explore the cutting-edge technology that makes it possible.

How do methane gas detector sensors work?

Detectors are of several types depending on the environment or usage requirements. They are available in portable or fixed versions, with batteries or power supply of different voltages, and essentially differ according to the mode of operation of the detection sensors with which they are equipped:

Optical sensors: Light detectives

Imagine a security laser that “smells” gas instead of detecting intruders. Optical sensors use infrared light to detect methane. When methane molecules absorb certain wavelengths of light, the sensor measures the change in light intensity, like a detective analyzing clues. These sensors work excellently in harsh environments even without oxygen. They are also immune to electrical interference, making them ideal for industrial areas. But they’re not perfect. Imagine trying to distinguish a single voice in a crowded room; optical sensors have difficulty distinguishing methane from other similar gases such as propane. Recent discoveries, such as the addition of graphene layers or hollow-core fibers, improve their accuracy.

Calorimetric sensors: Heat hunters

Calorimetric sensors act like miniature burners. They use catalysts (such as platinum) to ignite methane, releasing heat that the sensor measures. Like lighting a controlled campfire – the bigger the flame (or gas leak), the more heat is released and therefore detected. These sensors are generally cheap, robust and excellent for detecting explosive levels of methane in coal mines. But high heat can cause premature wear, and toxins such as sulphur can compromise their catalysts. Innovations like energy-saving microheaters and dual catalyst designs help them last longer and work smarter.

Pyroelectric sensors: Heat-to-energy converters

Pyroelectric sensors are the alchemists of the gas sensor world, converting heat into electricity. When methane gas interacts with a heat source, the sensor’s pyroelectric material (such as ceramic films) generates a voltage jump. These devices operate at room temperature and do not require oxygen, making them versatile. Unfortunately they’re expensive and bulky, closer in shape to a laboratory device than a tool to install in your kitchen. There are some recent advances though, such as the use of quartz tuning forks or laser-based systems that reduce their size and improve sensitivity.

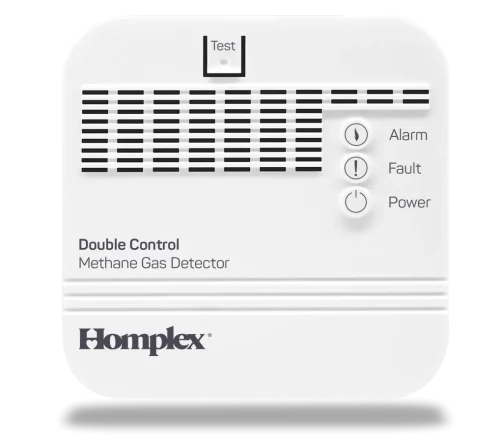

Metal oxide sensors: the rust ‘smellers

Have you noticed how some metals rust faster under certain conditions? Metal oxide sensors use this idea. When methane touches a semiconductor, such as tin oxide (Sn02), it changes the electrical resistance of the material. This change is measured and converted into an electrical signal proportional to the concentration of the gas. These sensors are affordable and durable, but need a continuous power supply to sustain the thermal reaction. Most detectors that contain metal oxide sensors – such as Homplex methane gas detectors – are designed to be powered directly from the mains.

Electrochemical sensors

These sensors work like a battery. Methane triggers a chemical reaction in a liquid electrolyte or gel, producing a measurable current. Newer versions use ionic liquids – salts that remain liquid at room temperature – to avoid leakage and evaporation. They’re excellent for detecting small leaks, but can be slow, like waiting for a Polaroid photo. Discoveries like laser-etched graphene electrodes are speeding them up, offering hope for real-time monitoring in homes and factories.

The future of methane gas detection

No gas sensor is perfect – yet. Humidity, temperature changes and gas mixtures (such as methane mixed with CO₂) can fool even the best devices. Imagine a sensor trying to hear a whisper in a thunderstorm; engineers are tackling the problem with moisture-resistant materials and signal microprocessors driven by algorithms and in some cases even artificial intelligence. The goal? A sensor that’s cheap, durable and accurate enough to detect a single molecule of methane in a soccer field.

Recent innovations close that gap. From drones equipped with optical sensors that scan pipelines to pocket-sized electrochemical detectors for households, the technology is getting smarter, smaller and greener.

Sound interesting? Read on with:

No Comments yet!